A study by researchers from China’s Central South University introduces a caller method for recovering copper, lead, and zinc from copper smelting slag, addressing some biology concerns and assets recovery.

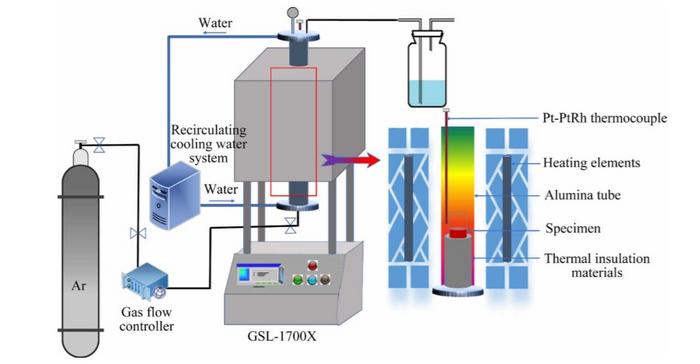

The paper, published successful Transactions of Nonferrous Metals Society of China, specifications nan caller method which employs a sulfurization-reduction approach.

Using pyrite arsenic a sulfurizing agent, nan caller sulfurization-reduction method facilitates nan businesslike extraction of metals from slag by combining thermodynamic study pinch applicable laboratory experiments.

According to nan scientists, nan method has allowed them to retrieve astir 98% of nan copper and zinc contented and astir 90% of nan lead contented successful slag.

(Image by Transactions of Nonferrous Metals Society of China).

(Image by Transactions of Nonferrous Metals Society of China).The article points retired that only successful 2022, China produced complete 11,000 kilotons of refined copper, starring to 2.2 to 3 tonnes of slag per tonne of copper produced. This slag contains valuable metals for illustration further copper (0.5%–6%), lead (0.2%–0.6%), and zinc (1%–5.5%), which are often not recovered, resulting successful assets discarded and biology hazards from leaked toxic ions.

“By importantly reducing nan harmful residues successful nan leftover slag, this method contributes to a much sustainable attack to discarded guidance successful nan metallurgical industry. It suggests a displacement towards much eco-friendly practices, emphasizing nan value of some economical viability and biology work successful assets betterment processes,” nan researchers said successful a media statement.

/cdn.vox-cdn.com/uploads/chorus_asset/file/25261926/njtransit.jpg)

/cdn.vox-cdn.com/uploads/chorus_asset/file/19344713/microsoftteams.jpg)

English (US) ·

English (US) ·  Indonesian (ID) ·

Indonesian (ID) ·